Bartleby, a S L O W Binding

Wednesday was materials research and skills acquisition day. Earl and I collaborated on commercial jobs in NYC, had some of the same friends, and spent many hours together either at his shop, or at my loft in TriBeCa.

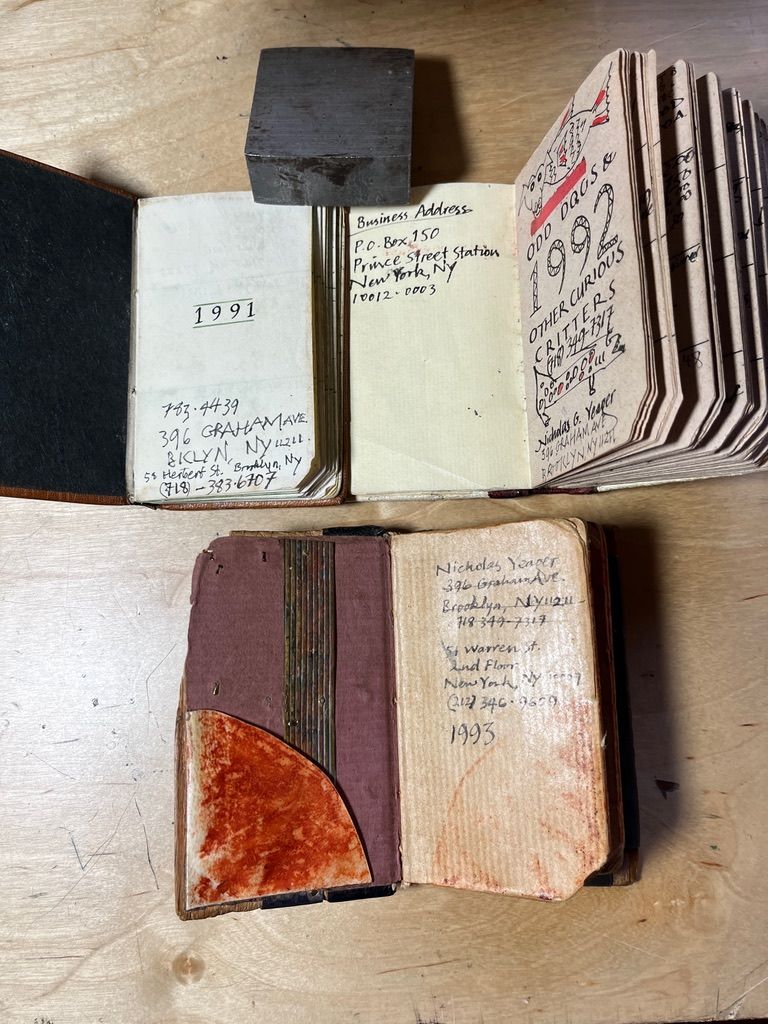

We talked until midnight Tuesday, and most of Wednesday morning reconstructing our earliest times together. Without the "medieval pocketbook" calendars I made every year, I wouldn't have been able to recall working together, moving, and clients we had at the time.

After working together briefly, I moved part of Earl's type and press materials from Spanish Harlem to Canal Street. When we met I was suffering from a 4 month regimen of prednisone and amoxycillin prescriptions given to me by an incompetent ear, nose, and throat doctor. I'd get bronchitis, he'd give me prednisone, then I'd get a sinus infection right after that, and I'd go on the antibiotic. Back and forth for all that time. I had no immune system, was sleeping 12 - 15 hours a day, and didn't know enough to kick that guy to the curb.

Earl kept telling me about raw food diets and how he could build my immune system back with blue-green algae, wheat-grass juice, cayenne pepper, and bursted grains. I didn't wanna hear about that kinda remedy, so I ignored his suggestions until the summer. Once I took the drastic measure of going this route, I was on my feet and energetic in about 3 days! Maybe I'll go into all that lead up to my moving to the Manhattan Ranch in TriBeCa in the future, but we're back in January, 2023 for now.

We went back to Berkeley, cold and drizzly. I suggested to Kallemeyn that he could have left the winter weather in NYC rather than pack it with him! Dropping it on us while we walked around the yard at Urban Ore wasn't very nice of him. Searching for old lumber that we might repurpose as boards was a pleasant experience in this unfamiliar weather, and the setting was appropriate for our brainstorming ideas about the binding design. Then we crossed the street to MacBeath's and looked at quarter-sawn oak.

When we returned, Earl collated one textblock. Then he folded it up into signatures, punched holes with a template, and I showed him how to sew on a sewing frame.

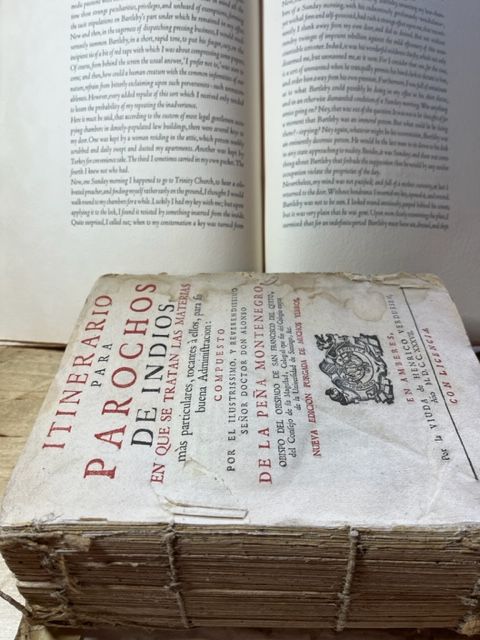

The one pictured here was made for me by Tom Conroy, a Berkeley bookbinder, and binding tool historian.

After an hour or so, Earl decided that his eyes just aren't up to the task. With the right pair of magnifiers, maybe, but he's dedicated to putting ink on paper, and decided that he wasn't going to be doing the binding of this edition. Which was fine by me, I have wanted to do this project for a long time, but understood his reticence to have it done on the opposite side of the country from his care and attention.

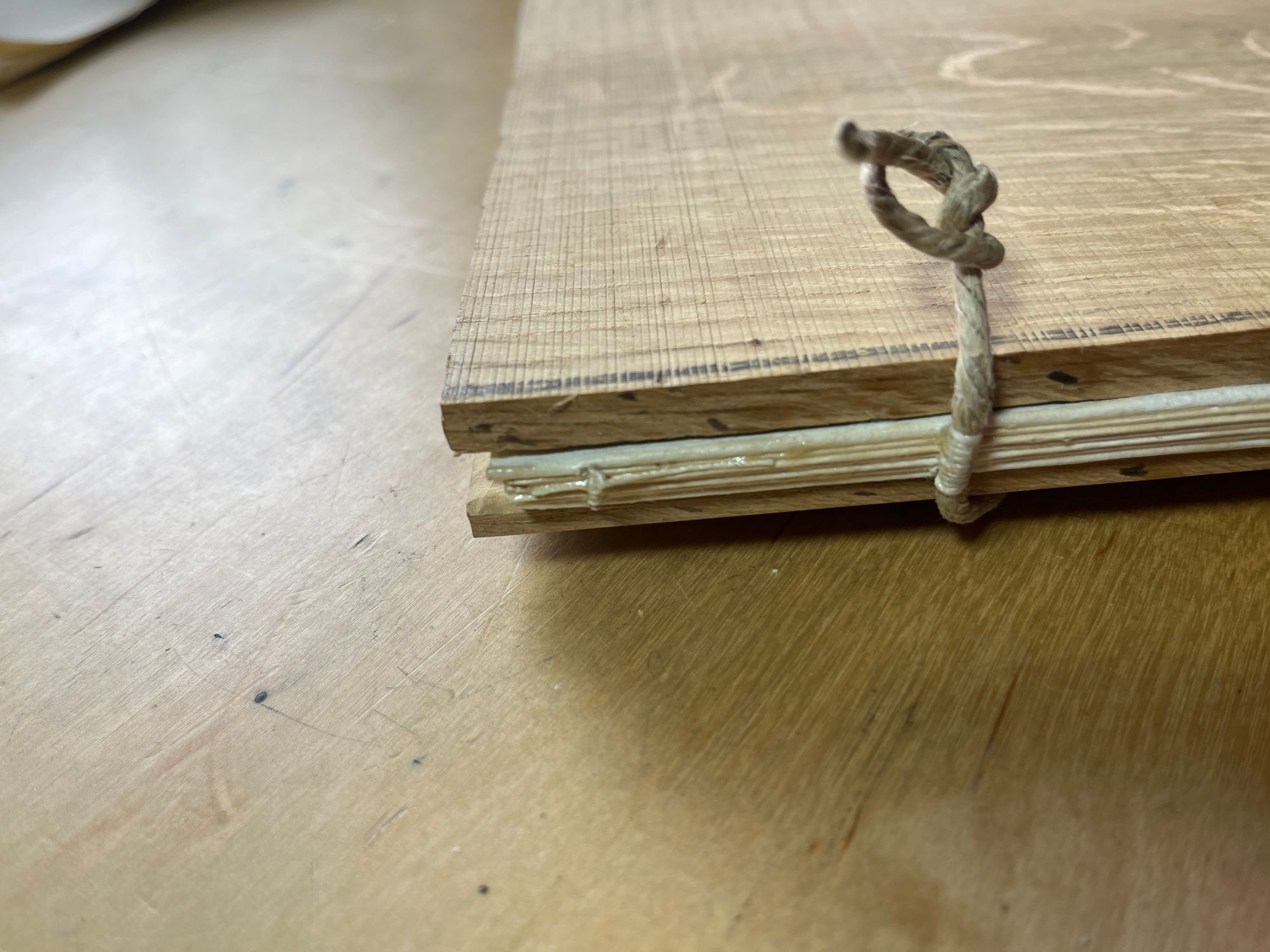

By nightfall, we'd come up with a new iteration for the binding; quarter-sawn oak boards, fairly thin – about 7 mm, or proud of 1/4" lightly chamfered all around. Of course, the spine would be shaped to accomodate the swell, but at 8 thin signatures, that's not a lot of swell!

I chose to pack-sew the textblock. This consolidates the sewing thread around the cord. There's no gap between the threads; instead of 8 threads, there's 11 wraps of the sewing thread around the cord. Because the signatures are thin, and this thread is relatively large for this, only a few extra wraps were needed. Pack-sewn books have a superior spine arc than those that don't. Each thread wrap snugs up against the next when the book is open, distributing the weigh load of board and pages evenly across the arc of the cord. Gluing up the spine, spine liner and leather covering consolidate the hinged signatures and boards to move as one mechanism. Lacing the cords onto the boards integrates the boards into that system reducing the chance of a detached board or split spine.

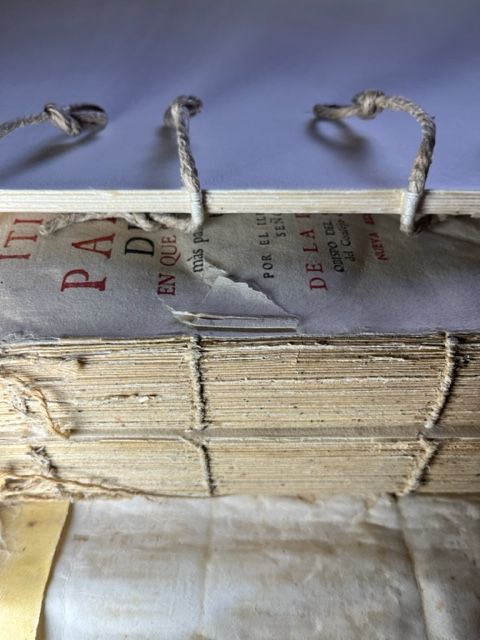

Is this really necessary on a book this thin? Maybe not, but why not give it the best mechanical treatment as it doesn't take that much longer. Take a look at the difference in a book (with too small cords for the number of signatures, and size of the textblock) where it wasn't done.

Next up is the leather, endpapers, and metal on the covers, and then the visits.